Humanoids are improving fast. Costs are falling. Capabilities are rising. But behind the progress is a fragile supply chain built on a few countries, a few materials, and a few factories.

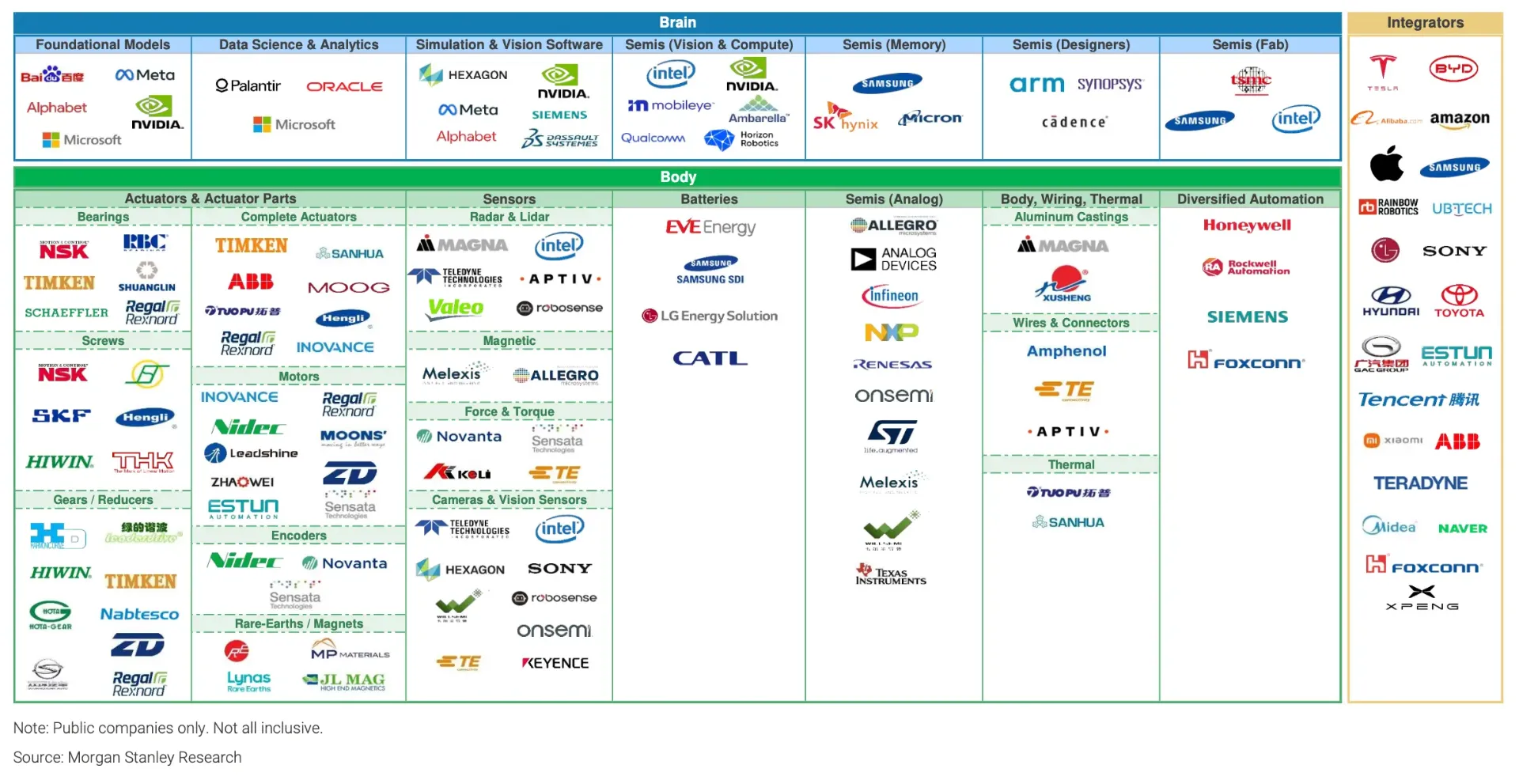

Most actuators depend on rare-earth magnets processed mainly in one country. AI chips come from a handful of advanced fabs in East Asia. Precision actuators, harmonic drives, batteries, and sensors are highly concentrated in specific industrial clusters. If any one region faces export bans, political tension, or shipping delays, entire humanoid production lines can stall.

We are already seeing reactions. Japan is building an “All-Japan” humanoid supply chain. The US and EU are rapidly reshoring motors, magnets, and semiconductor manufacturing. China is tightening control on rare-earth exports. This challenge becomes even bigger in a divided world. Trade restrictions, geopolitical competition, and industrial nationalism can easily disrupt the flow of key components. If humanoids become essential to logistics, healthcare, construction, manufacturing, and defense, then supply shocks could impact entire economies.

But there is a major opportunity we often ignore, the Global South. Countries in Asia, Africa, Latin America, and the Middle East can play a decisive role in stabilizing the supply chain. The Global South holds massive reserves of critical minerals like cobalt, nickel, rare earths, and lithium, and is rapidly developing strong manufacturing ecosystems in countries such as India, Vietnam, Indonesia, Mexico, and Brazil. These regions also have a growing pool of aspiring and young engineering talent capable of contributing to advanced robotics, materials, and battery technologies. Combined with their strategic geographic locations, these nations can significantly reduce global over-dependence on single supply routes and help build a more diversified and resilient humanoid robotics supply chain.

We need new strategies

- Build regional supply clusters across Asia, Africa, and Latin America.

- Support mining-to-manufacturing transitions, process locally.

- Strengthen partnerships for motors, batteries, actuators, chips, and sensors.

- Invest in inventing new materials and alternative actuator designs to reduce rare-earth dependency.

- Shift from “just-in-time” to “just-in-case” for critical components.

- Create transparent, trust-based sourcing frameworks among aligned countries.

Bottom Line

The future of humanoids depends on a supply chain that is diverse, distributed, and geopolitically balanced. A resilient robotics world needs shared responsibility not single points of failure. And the Global South is not optional. It is essential.